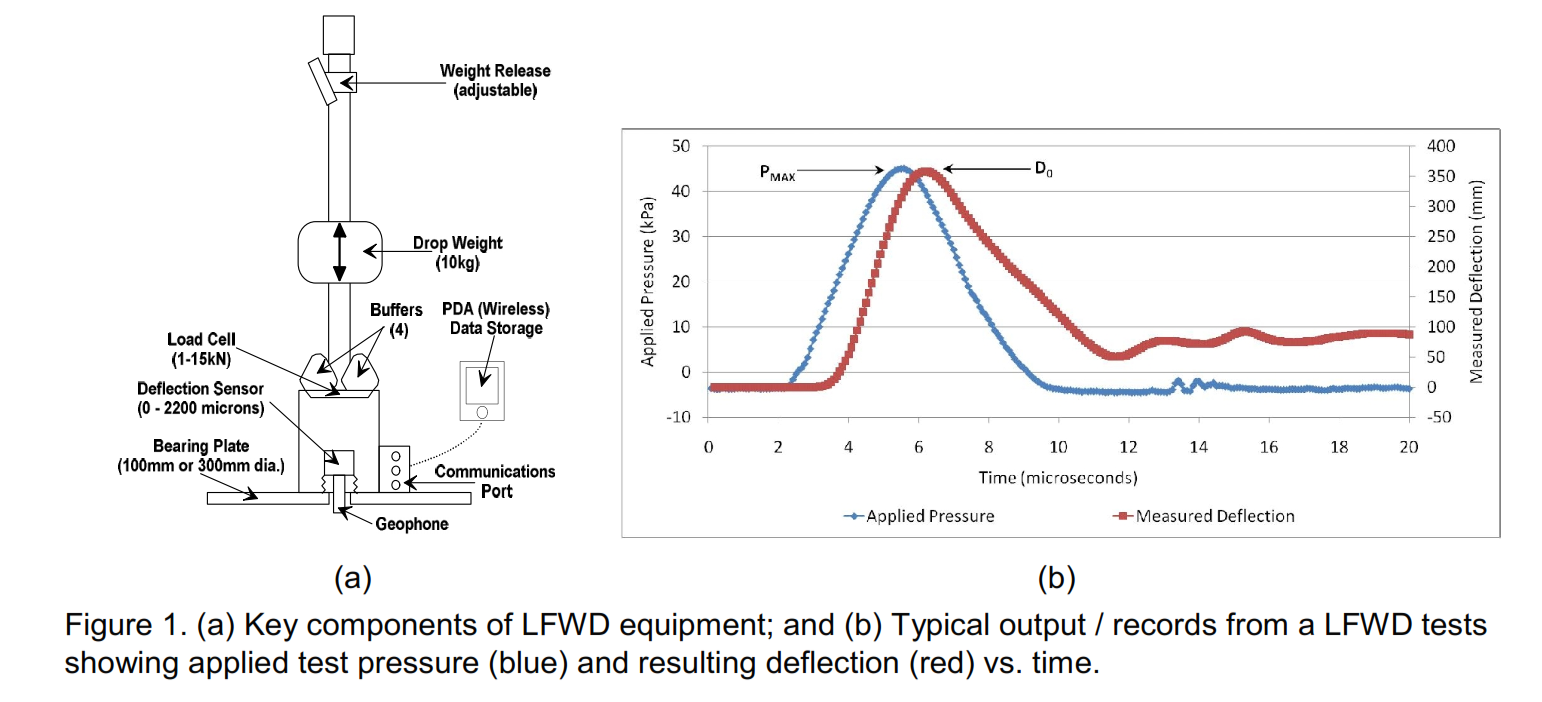

The Light Falling Weight Deflectometer (LFWD) equipment measures composite in-situ modulus value of near-surface materials. The modulus parameter returned by the test is a function of the peak applied loads and associated peak deflection. Figure1(a) show the key components of the equipment, whilst Figure1(b) presents typical results of a test. These results are then transformed into an in-situ modulus parameter (ELFWD) via use of classic static elastic theory (Boussinesq elastic half-space) equation.

The use of a modulus parameter is becoming preferential for incorporation into design (e.g. mechanistic-empirical design guide, MEPDG, in use for design of FHWA projects in US). However, the current state of practice is to base the parameter selection on the result of a non-deformation parameter, such as DCP or CBR results from site investigation or density/moisture relationships in earthworks QA. This means that there is currently a disconnect between design and construction control.

The LFWD addresses this gap, and is finding support and gaining popularity based on the acceptance and success of the Falling Weight Deflectometer (FWD). Whilst LFWD technology is relatively new to Australia and is not yet a ‘standard’ test, it is widely used and accepted in Europe.

Key applications and advantages of LFWD testing are:

- In-situ testing of earthworks during construction, particularly where common techniques (e.g. nuclear gauge/sand replacement) are not appropriate or cost effective;

- Equipment of higher precision than a typical tests (e.g. DCP) used for QA of allowable bearing capacity of prepared surfaces–prior to the installation of permanent (slabs, footings,pavements) or temporary (crane pads);

- Estimation of in-situ modulus of soil in a very quick turnaround time. This allows the use of the equipment to support (and supersede the turnaround time) traditional test results, such as soaked CBRs;

- As a surface based test, LFWD has no footprint that needs to be remediated, and is cost-effective for completion at locations where equipment/plant has to be stopped whilst test is completed;

- LFWD is more accurate than DCP, especially in soft/loose materials i.e. in locations where existing bearing capacity is an issue, LFWD would be preferred investigative tool;

- Can be used to assess in-situ modulus/strength for working platforms.